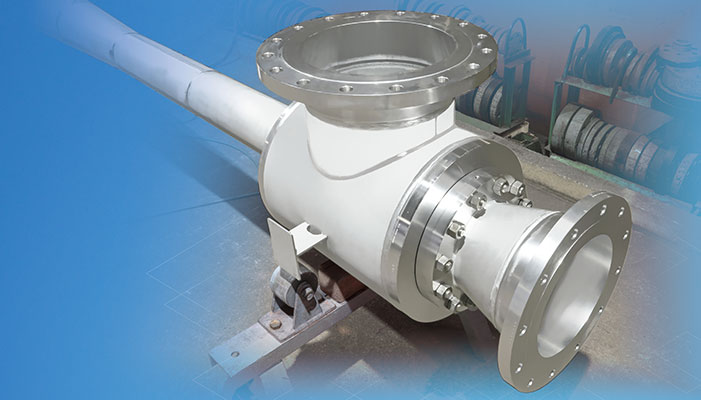

The accelerated flow with dropped static pressure passes through the throat this causes further movement of the secondary phase from the suction port into the motive stream. The two-phase mixing results in the induction of pressure shock waves of high frequencies. The potential energy in two phases is converted to kinetic energy through a special case of Bernoulli-Venturi effect, where flow mixes and accelerates through the mixing chamber.

This momentum exchange is defined by the momentum exchange coefficient which is a function of drag coefficient, bubble size and phase velocities. During this momentum exchange of primary fluid into secondary, the secondary phase forms dispersed bubbles inside the primary flow stream. In the case of ejectors, the jet passing nozzle induces steady flow eddy current to its surroundings, at the suction chamber, due to momentum transfer, which accelerates the secondary flow. The new system was developed with SS 303 material and ensured periodic cleaning of scales. The installed system was not able to meet the vacuum requirement after being in operation for thirty-six years, pumping hot and dirty gases from steel at a temperature of around 3000 ☏. A case study from National Forge Company, PA, recommended vacuum degassing through ejector, as an essential step in producing high quality steel. This vacuum is increased at different steps by regulating motive flow.

After placing of the ladle/mold in the cooling chamber, degassing is performed, which ejects hydrogen, oxygen, nitrogen and other dissolved gases trapped within the mold, ensuring cleanliness, ductility and toughness of the steel. In steel industries, larger rejection due to voids and strength led to adaptation of ejector-aided vacuum cooling. The physics of vacuum generation and formation of recirculation bubbles on circumference of jets has been visually explained by Kumar et al. explains the influence of zero secondary flow on unsteady phenomenon in vacuum ejectors.

There is zero secondary flow, while using ejectors as a vacuum pump. They are used in vacuum packing, drying, evaporation, gas ejection, etc. The fact of installation flexibility and efficient operation supports ejectors as a suitable alternative for vacuum generation.

0 kommentar(er)

0 kommentar(er)